Sheet metal manufacturing

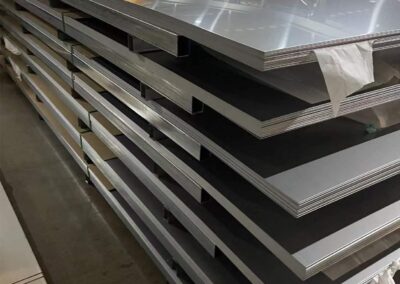

Sheet metal is a type of iron or steel sheet produced by hot or cold rolling processes, and is characterized by its flat surface and ease of shaping, cutting, and welding. Sheet metal is widely used in various industries due to its strength, flexibility, and variety of types, such as black, galvanized, cold-rolled, colored, and perforated sheet metal.

Sheet metal is considered one of the most important metal materials used in various fields such as construction, door and facade manufacturing, household appliances, pipes, metal structures, and engineering industries.

Sheet metal is considered one of the most important metal materials used in various fields such as construction, door and facade manufacturing, household appliances, pipes, metal structures, and engineering industries.

Advantages of sheet metal

A variety of types and sizes

To meet the needs of various industries

Easy to form and weld

It can be manufactured in multiple shapes

High strength and durability

Makes it suitable for various applications

Cost-effective

compared to other alternatives in the metal industry

Smooth and precise surface

A smooth and precise surface in the case of cold sheet metal facilitates painting and finishing processes

Corrosion and rust resistant

(Especially galvanized and colored sheet metal)

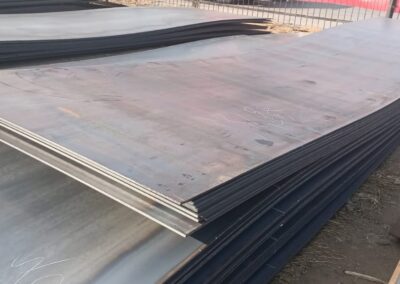

Black sheet metal (plain flat)

Description: Manufactured by (Hot Rolled)

Advantages: High strength – Easy to form – Heavy-duty

Uses: Hangars, metal structures, bridges, heavy industries

Advantages: High strength – Easy to form – Heavy-duty

Uses: Hangars, metal structures, bridges, heavy industries

Corrugated Sheet Metal (Coiled or Rolled)

Description: Comes in coils of varying lengths.

Advantages: Easy to transport and store – Cut to order.

Uses: Pipe manufacturing, metal forming, various sectors

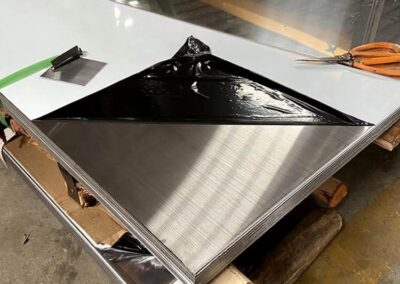

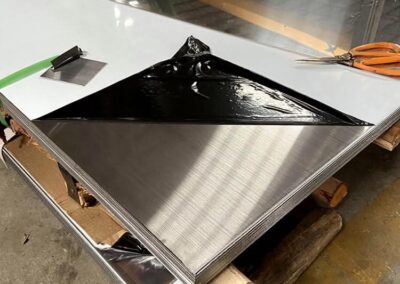

Cold Rolled Sheet Metal

Description: Produced by cold rolling after hot rolling.

Advantages: Smooth surface – Precise thickness – Easy to paint.

Uses: Home appliances, automobiles, power tools.

Advantages: Smooth surface – Precise thickness – Easy to paint.

Uses: Home appliances, automobiles, power tools.

Perforated Sheet Metal

Description: Sheet metal with regularly shaped perforations.

Advantages: Lightweight – Ventilated – Aesthetically pleasing.

Uses: Ventilation grilles, air filters, metal decorations.

Advantages: Lightweight – Ventilated – Aesthetically pleasing.

Uses: Ventilation grilles, air filters, metal decorations.

Stainless Steel Sheet Metal

Description: Sheet metal made of stainless steel.

Advantages: Rust and corrosion resistant – Easy to clean – Elegant appearance.

Uses: Industrial kitchens, hotel and restaurant equipment, medical industries.

Advantages: Rust and corrosion resistant – Easy to clean – Elegant appearance.

Uses: Industrial kitchens, hotel and restaurant equipment, medical industries.

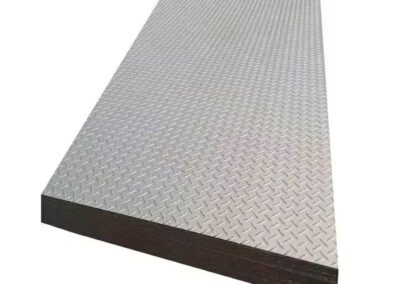

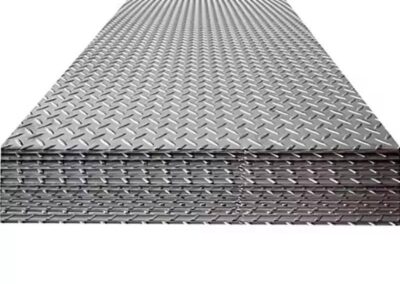

Steel expanded sheet

Steel expanded sheet is a type of metal sheet characterized by its textured surface with raised patterns resembling baklava or a grid pattern, giving it an aesthetically pleasing appearance and increasing surface friction.

It is usually made of iron, stainless steel or aluminum, and is widely used in industrial flooring, stairs, trolley surfaces and walkways to reduce slipping.

Steel expanded sheet is characterized by high durability, corrosion resistance, and ease of cleaning and maintenance, making it ideal for use in harsh environments and high-traffic areas.

It is usually made of iron, stainless steel or aluminum, and is widely used in industrial flooring, stairs, trolley surfaces and walkways to reduce slipping.

Steel expanded sheet is characterized by high durability, corrosion resistance, and ease of cleaning and maintenance, making it ideal for use in harsh environments and high-traffic areas.

Pine steel sheet

Pine steel sheet is a type of iron sheet characterized by a slightly wavy or corrugated surface, also known as corrugated or wavy sheet metal. It is usually made of galvanized, black or painted iron, and is widely used in roofing, wall lining, and the manufacture of hangars, warehouses, wagons and trailers. Pine steel sheet is distinguished by its high resistance to weather conditions such as rain and sunlight. It also offers added strength and lightness, making it easy to transport and install. It is an economical and durable choice for construction projects and industrial and agricultural applications.